I happened to be out at our warehouse in Columbus, Ohio when the staff was busy creating the 150 Palette Value Pack. I had heard about the process, but had never seen it in action.

I write much of the software for the warehouse (to receive the boxes, move inventory around, keep track of it, and then send it on its way), so I was curious to see how they managed to create a 150-item kit accurately. It turns out that it is all one woman – PK. She retired from her regular job about 10 years ago, got bored sitting at home, and has been working at Crafts ever since.

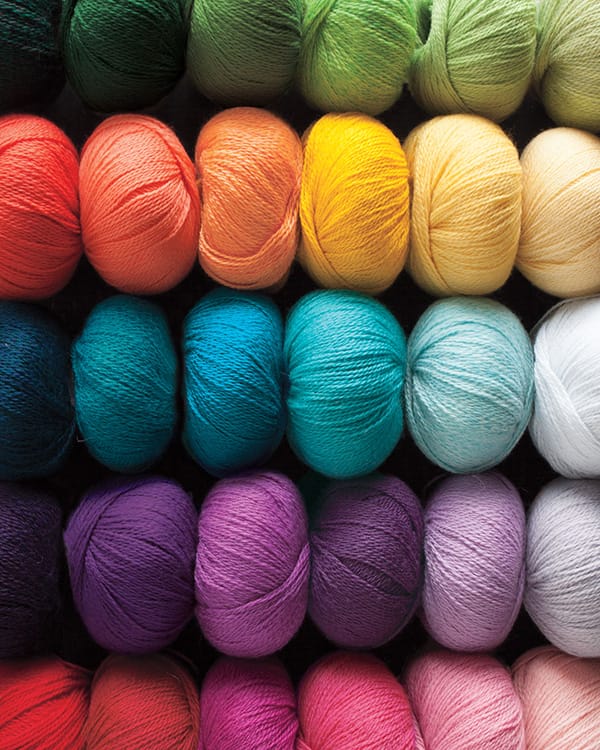

PK has developed a system to sort the yarn into boxes accurately. She is the only person allowed to create these kits. She works with the folks in the receiving department to pull 50 balls of each color. She stacks them, and double-checks to be sure she has all 150 colors.

She then lays out 50 boxes to hold the yarn kits, separated in chunks of 10, since each bag of yarn holds 10 balls. If she sorts the balls in batches of 10, she immediately knows if there is a problem. With only a maximum of 10 boxes to check if something goes wrong – like she has too many or too few balls at the end – it speeds up her time.

It takes about a day to collect all the needed colors and go through her list to make sure none were missed. And then another day to day and a half to sort the yarns into boxes.

Ta da! All done, and ready to ship out to a customer.

Just as she was finishing up, our newest Crafts family member came by for a visit. Here PK is with Ivy, the new baby of Andre, the head of the receiving department, and his wife, Jenny, who also works in receiving.

If you ever order one of our Palette Value Packs, this is how the magic happened!

Save